Korond – A Transylvanian village where “every man is a potter”

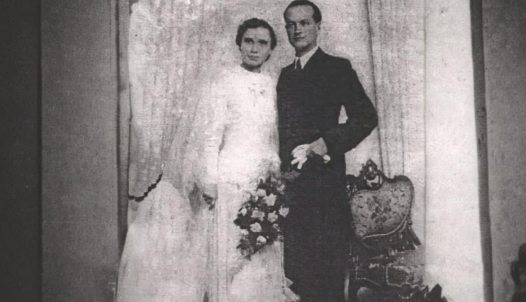

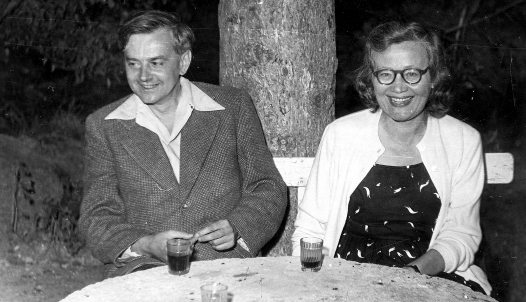

"The clay turned / would have run, / but then it gave way to form, / and my father watched like a god / what his wits and blood could do" – wrote Lajos Páll poet about his father, who was one of the most prominent figures of the centuries-old tradition of pottery in Korond. The tradition is still alive today, and the village is one of Transylvania's must-see destinations, with a range of booths lined up along the main road, demonstrating how timeless and long-lasting forms can be created from a simple piece of clay.

From salt to clay

"Korond has little arable land being at the foot of the mountains, but on the vast mountain hills it has more pasture, and that is why cattle breeding is the main factor here, and the pottery, because in Korond every man is a potter; Here are made the unglazed and unheard-of cheap clay pots, which cover the kitchen utensils of all Szeklerland (except Csík); hundreds of thousands of these products are carried by the people of Korond in their creaking carts, and are usually sold not for money but for grain. They go from village to village, from market to market, and carry home grain to their families making hay in the fields", wrote Balázs Orbán in his book The Description of Szeklerland, published in 1868, about Korond, a village in Harghita County, Transylvania, famous for its pottery.

Today the village is home to more than five thousand five hundred people, but its history dates back to the 14th century. At that time, the Papal tithe register referred to a small group of houses on the side of the nearby Mount Korond as Kurund. Agriculture was not the only source of livelihood in this mountainous valley area lined with streams, as one of Europe's largest salt deposits is also found here, in the Transylvanian Salt Lands. So it is not surprising that until the Szekler uprising of 1562, the village relied primarily on salt mining.

It was then, however, that the Szeklers lost the right to trade salt, and for a few decades, even families were not allowed to freely mine the precious mineral for themselves.

It was necessary to adapt to the changed circumstances, and it was at this time that the people of Korond turned to pottery. The first written evidence of this dates back to 1613, but at that time it was far from appreciative. The guilds of Udvarhely accused the craftsmen in Korond of being bunglers. The matter did not stop there, first in 1643 György Rákóczi I, and then four decades later Mihály Apafi issued a decree to protect the potters of Udvarhely. Since the livelihood of the people of Korond depended largely on the pottery they sold, they not only regularly broke the sales ban, but also expanded their production, including the making of stove tiles, as evidenced by a surviving tile from 1667.

Pottery for all!

It was not until 1750 that the situation eased, when Count László Gyulaffy, the Transylvanian Chancellor, allowed the potters of Korond to hold a fair four times a year to sell their wares. At first they sold their goods in the surrounding villages, but soon they began to expand beyond the Carpathian Mountains – a boom in exports was halted by the Austro-Hungarian-Romanian customs war of 1886, which lasted five years.

"The potters of Korond can be divided into two groups: there were the so-called back potters, who, not having a cart, would rise early in the morning and descend to the surrounding wealthier villages (Énlaka, Etéd, Sámonfalva, Keresztúr, even as far as Udvarhely ) with their backpacks full of pots or simply pots tied together. The second group of potters were the carters: from the end of the 18th century, their carts supplied the Mezőség region with unglazed pottery and red pottery, and later on, the pottery from Korond found an excellent market beyond the Carpathians, especially in Moldavia, but also in Havasalföld", wrote Zoltán Tófalvi in his study entitled The pottery of Korond, published in the Hazai Tükör magazine in 1972.

In addition to pottery, the folk crafts of Korond include the processing of tinder fungus, which has long been used to make fire, but the people here used it to make hats and ornaments.

Glazed boost

The opening of the State Stonemasonry and Pottery Vocational School in Székelyudvarhely in 1893 boosted the pottery in Korond. The aim of the institution was not only to enhance the industrial development of the town and the county but also to "allow the hands and craftsmen of the stone and clay industry to learn how to produce more valuable and better products from the material they had been using, with less effort but with more sense. (...) To make it possible for our poor craftsmen and our poor rural Szeklers, who are farmers in the county, not to be forced to cripple their children in the work they have been doing, but which does not provide them with a livelihood, but to train them for a career in the stone-cutting and clay industry which will provide them with a livelihood. In this vocational school the education is free of charge" – reads the 1892 issue of the Kolozsvár newspaper.

With the availability of modern skills, pottery in Korond began to take off, and while in the 1820s there were fifty masters, by the turn of the century this number had risen to over three hundred and sixty. The school also introduced the latest techniques of the time, including glazed pottery, which was gaining ground at the end of the century and was quickly adopted even by the older masters in Korond thanks to the young apprentices.

In the same period, Gyula Gáspár opened his workshop for the production of glazed pots. "Gáspár wants to revive the old Szekler pottery and besides selling cheap goods, he does not lose sight of art and beauty and uses the Hungarian and old Szekler style as a very attractive decoration in his products. It feels good that we have to say this well-deserved praise about a craftsman who is actually only a newcomer in this field because he used to work as a clerk" – reported the January 1908 issue of the Hungarian Glass and Clay Journal.

In the beginning, the potters of Korond made mainly red, unglazed cooking pots: pots for puliszka, cabbage, milk, and sauerkraut, as well as pots for making plum preserves, which were all ideal for use on the potted stoves of the time.

In addition to these, jugs, bowls, and pots for carrying food were also very popular. The most common motifs on pots and pans were the bird of peace, the tulip, the family tree and various coats of arms. The white glaze base is typically painted in blue and black with red - the Saxon blue-on-white motifs and non-traditional fancy vases appeared between the two world wars.

The beginnings of mass production

After the First World War, the history of pottery in Korond continued, with the first significant change coming at the turn of the 1920s and 1930s. First, the Bertalan-Kacsó factory, then the Katona Works, two privately owned ceramics factories, began operations, followed in 1936 by the short-lived Patria. It was also in this decade that the Szepesi Cooperative, a group made up of private potters, was established. By the 1940s, ceramics from Korond were known throughout Europe. After the Second World War, the ceramics factories were nationalized, but pottery continued to be the main source of livelihood in the village.

"In Korond, a manufactory-like ceramics factory was established in 1951, currently employing 140 workers and producing around 3 million lei worth of goods annually. In the autumn, they will start expanding the production plant, because, as Lajos István, the master ceramist, says: "They could sell three times as much as we produce now. Twenty-five foreign countries, from Canada to Japan, have ordered 25,000 flower plates and 100,000 pitcher jars for their guests on the coast, who can take those with them as souvenirs", wrote the 1968 issue of Új Élet (New Life) magazine.

The zero step in making pottery was digging, cleaning and grinding the clay, which is rarely done by potters today, as the raw material is easy to buy now.

The real challenge starts with the throwing, which requires a lot of patience and skill to mould the shapeless clay balls into form.

Once the form is ready, the pottery can be primed, when the pot is given its white base colour, followed by painting - traditionally done by the women of Korond. The final step is firing, which takes eight to ten hours in a kiln at over 900 degrees Celsius, followed by glazing and re-firing.

The production of the unique black ceramics started in the 1960s, and in 1974 a new factory was established, which became a joint-stock company under the name Vestra after the regime change. Production at the plant ceased in the mid-1990s, and pottery production in Korond was completely taken back to the potters' workshops. Of the seventy or so pottery centres that once existed in Transylvania, only Korond remains, where today more than 600 craftsmen produce the well-known pottery, preserving traditional techniques such as firing in wood-fired kilns. As a must-see destination for excursions to Transylvania, the popularity of Korond pottery remains steadfast.

This article was written with the support of the Carola Association.